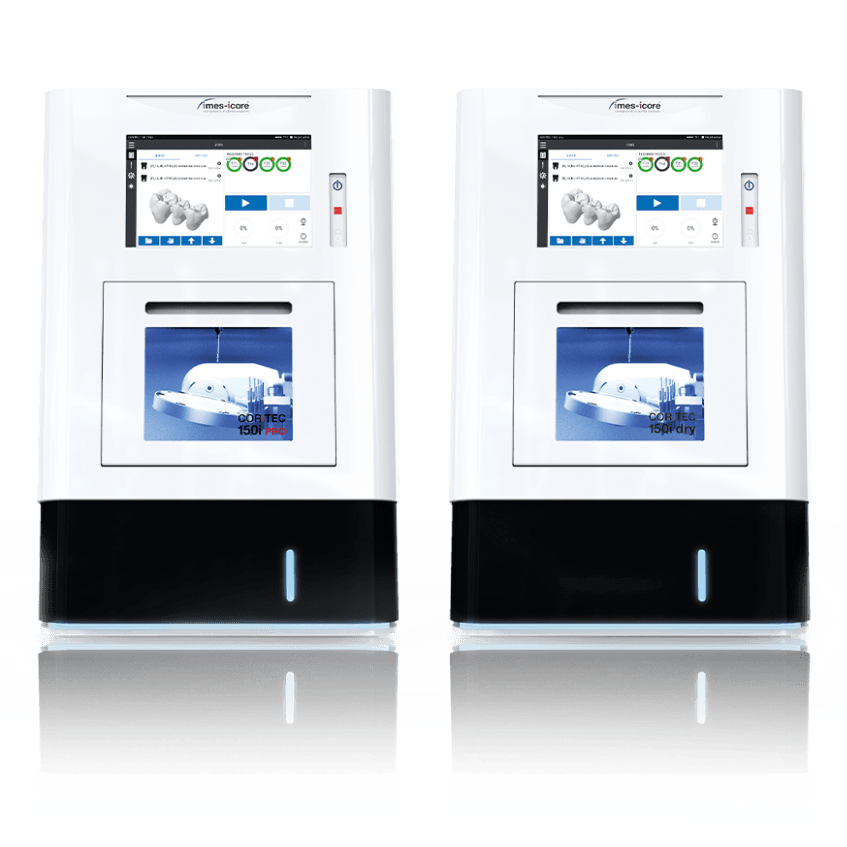

Milling Machines

Imes CORiTEC 150i

The extremely stable design of the mono-block cast body enables precise machining in round blank and block form. The machine‘s small dimensions and 5-axis simultaneous technology offer a unique ratio of machine size and functionality. An exceptional ratio of power, speed and precision – this is what the powerful high-frequency spindle with 750 W and 100,000 rpm offers. Thanks to the quick-clamping system, the various holder systems can be changed quickly and easily – while maintaining the same precision. Time-consuming calibrations are therefore unnecessary.

Help find the ideal mill for my lab

Benefits

- auto calibration*

- automated cleaning function*

- metal processing**

- turn-milling-grinding-processing possible

- novel, closed mono-block cast body for highest stability and precision

- no external PC required

- half-open blank holder C-Clamp (optional)

- ionizer inclusive

- high precision due to integrated temperature compensation

- wet and dry machining possible

- minimum external compressed air, only 3 bar required

- short amortization period

- minimal footprint